What You Need To Know When Purchasing Your First Wood Chipper

Are you looking at purchasing your first wood chipper?

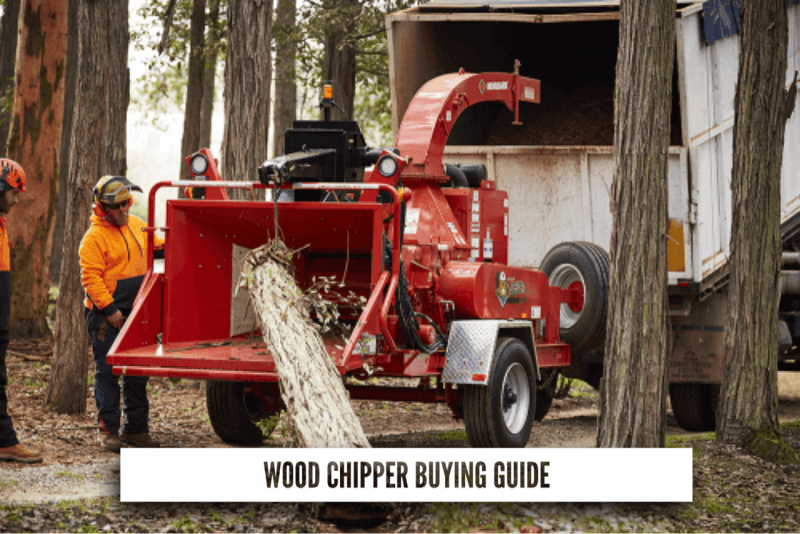

Normally wood chippers are used to turn wood elements into small pieces and bits. The machine can be used for cleaning an area of debris like dead tree limbs and fallen branches, which can be even more common after such weather events as strong storms. This makes your own wood chipper a highly valuable tool for tree service companies, lawn maintenance and waste removal.

A wood chipper may also be used to clear a yard of small trees and overgrown brush. You will then have a lawn that is clean and free of blockages as well as a pile of wood chips that can be used as mulch.

If you’re looking to become a wood chipper owner, here’s what you need to know.

So, how does a wood chipper work?

Wood is fed into the chipper by workers where there are rotating knives that move at the speed of 1000–2000 RPM for chopping up pieces of trunk, tree limbs, and branches until they get reduced to thin small chips. Small amounts of power are demanded by a wood chipper to work, and that comes from either petrol- or diesel-powered internal combustion engine.

Make sure you double, even triple check which fuel is suitable in the Wood Chipper you are using. We have seen this to become a problem with companies renting out Chippers. If you do make this error you may need to get in touch with a fuel draining service company.

When a wood chipper is used you can save a lot of effort and time compared to chopping each piece down to size individually using a chainsaw or ax. The user also needs to use all of this raw power responsibly. Trying to prepare safety guidelines and follow them can end up in serious injury or sometimes can even be fatal.

9 wood chipper safety guidelines to remember.

Whether you are experienced with using wood chipper or brand new, it is a good idea to educate yourself regarding the proper and safe functioning of wood chippers.

The following are 9 safety tips to get you started.

1. Make sure to read your users manual

It is important to read the operator’s guide and understand it in addition to other important related literature. Everything you need to learn about your new machine is included in the manual: safety instructions, machine parts, operational constraints, and technical specifications. There are many moving parts on a wood chipper and it is definitely important to be aware of the potential dangers and usefulness of each of the components.

2. Wear the correct working gear

When using a wood chipper, wear short-sleeved, tight-fitting clothing. Make sure our trousers and shirts are tucked in properly and take off anything that can get caught in the machine such as straps, ties, belts, jewellery or any other hanging items. Make sure your garments also do not have cuffs.

When using a chipper it is critical to wear personal protective equipment and is required by regulations by many governments and states. When using a wood chipper standard safety equipment includes steel-toed boots, cuff-free heavy-duty work gloves, ear protection, safety goggles, and a hard hat.

Most deaths caused by wood chipper occur when the operator of the machine gets caught up and then destroyed by the cutting knives and feeding mechanism. Eliminate any possibilities where your clothing might get snagged on the wood that is getting fed into the wood chipper.

3. Inspect before using

Before operating your wood chipper be sure to inspect all of its parts first. If you find any defects such as broken hood latches, worn hinges, or cracks don’t use your machine. Make sure all bolts and screws are tight. Examine all safety devices and controls to confirm they are working properly.

4. Clear the perimeter

Before you start the machine, clear the area of animals, children, and bystanders. Establish a minimum 10m safety perimeter in all directions surrounding the wood chipper and make sure the perimeter is marked clearly with warning devices like signs, barricades, and cones. Turn the machine off immediately if you see anyone approaching.

According to the domestic waste removal experts at Bargain Bins, having space can also help with clean up, they explain “we remove wood chipped waste regularly and often find that people did not think where the wood chip waste would go. Wood chipping in an open space where you can get access to remove the waste is just as important as doing the job in the first place.”

5. Eliminate any obstructions

Make sure to eliminate any tripping hazards and obstructions surrounding the wood chipper. The area around the machine needs to be kept free and clean for unobstructed and easy movement.

Do not allow the wood chips to pile up, and turn off the machine when the pile gets too big. Empty it and keep it away from your chipper. That will help to reduce the chances of you slipping and falling around the machine.

The simplest way to eliminate obstructions is to find a clear space to begin with. This can actually protect your property according to the team at KJ Concreting who explain “incorrect use of a wood chipper isn’t just limited to personal injury. When used too close to the home we’ve seen damage to paths and walkways due to the machinery that could easily have been avoided by finding a clear space.”

6. Always work with a Partner

When using a wood chipper, it should always be operated by 2 or more people. Never use a chipper by yourself. When you are feeding wood into the wood chipper, there should be another person on alert close to the emergency stop button, console, or another security device on the machine.

7. Start out on the lowest setting

To get started with operating a wood chipper, begin by running it on the lowest speed available. Listen closely to the noise coming from the chipper.

It can be challenging for first-time wood chip owners to diagnose problems, which can lead to safety problems according to the domestic demolition experts at Northern Rivers Demolition. They provide an exclusive tip, saying “if there are any unusual sound, there could be broken or loose components inside and you should turn off the machine immediately. Have an expert inspect and repair it.”

8. Check the load

When pieces of wood that are too wide and large are fed into the wood chipper it can increase the chances of the machine becoming damaged and workers getting injured. Only load material into the wood chipper that fits within its constraints. If necessary, cut down the timber to the proper size before it is fed into the wood chipper.

9. Keep your distance

Keep a distance from the wood chipper after it captures the timber you have added. That will reduce the chances of you getting caught up with the timber and ending up on the floor in small pieces with the wood.

Looking for more guides to machinery? Find out what to expect when buying a stump grinder here!

Author Bio

Colyn Emery is a passionate freelance writer based in Sydney. She is a university student majoring in philosophy with a hunger to learn. Colyn loves to travel and in her spare time enjoys being.